We are committed to producing our whisky in the most responsible way possible. We follow what we believe is the lightest touch approach to distilling, including adding value to co-products and empowering a realistic and tangible circular economy.

In 2024 we achieved 'Global Sustainable Distillery of the Year' in the Whisky Magazine's Icon's of Whisky awards. Our dedicated team of people work hard to make changes and improvements where we can make a difference, being recognised for our work means a lot to us.

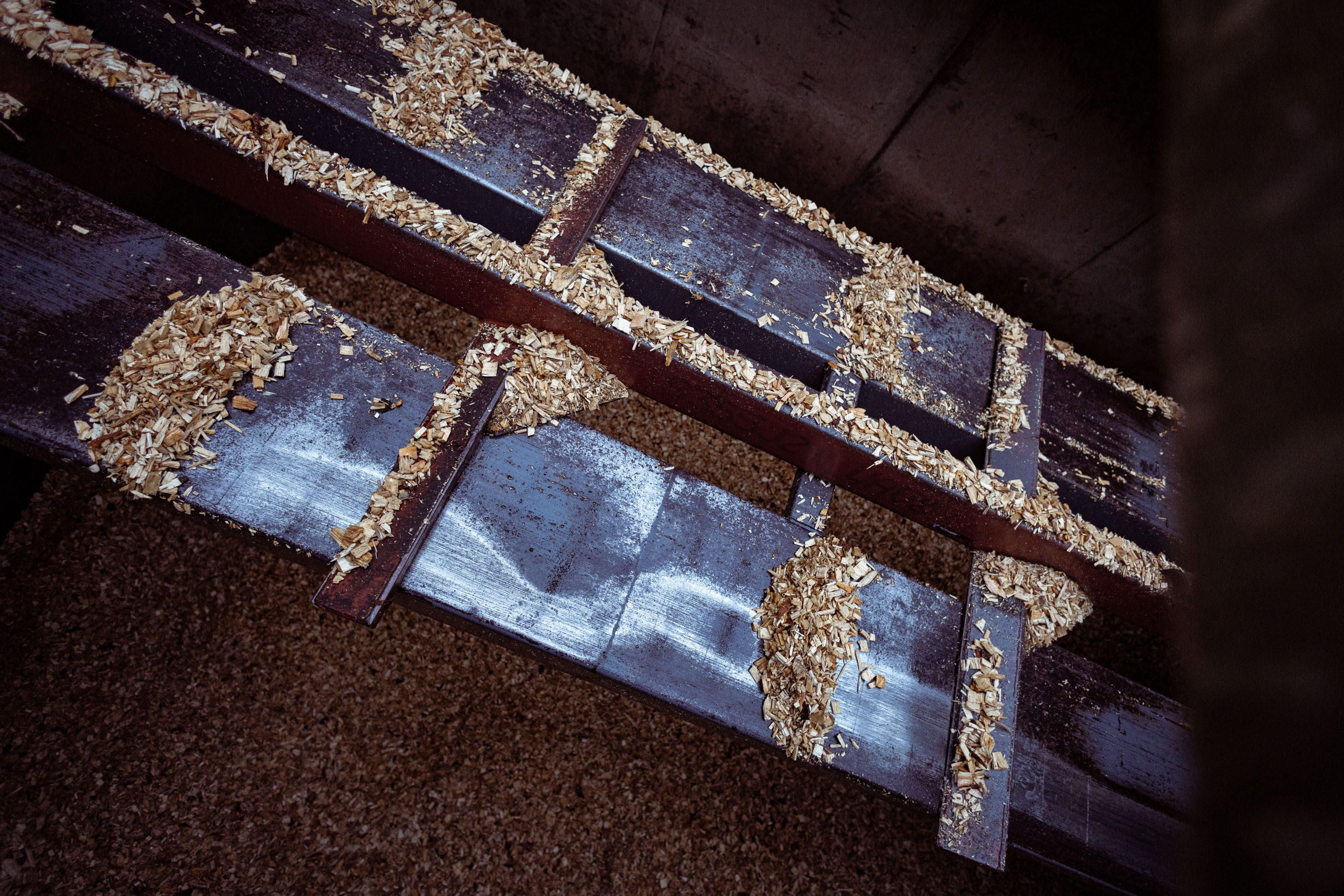

Biomass

Our wash and spirit stills are heated up by steam, generated by our woodchip biomass boiler. The woodchip we're using is from locally planted forestry, originating fewer than 15 miles radius of our distillery. The forestry site has a detailed 100-year plan to re-plant with tree species native to the peninsula.

The excess steam also heats up our Visitor Centre and the surrounding houses.

Water

Glenmore river supplies the distillery’s cooling water and has a hydro-electric generator which provides the local grid with power that we use in our daily running of the distillery.

In 2018 we installed a watermiser to reduce the amount of condenser cooling that water we use from the river from 400m3/day down to 20m3. The only water now required is to the top up for loss in evaporation which leaves a nice steady flow of fresh water in the river.

Solar Panels

We installed 138 solar panels in spring of 2023. Scotland is not exactly famous for its sunshine, but the capacity of these panels is 50kW which will help towards the distillery's energy usage and we can add excess energy to the local grid network, on a sunny day.

Woodland Renewables

Woodland Renewables is a local renewable plant which supplies us with their locally harvested woodchip. Our partnership with them results in the distillery putting funds back into the local economy, supporting jobs and the community.

We supply them with our co-product, pot ale, which they reduced down to a syrup. The heat required for the reduction is also acquired from woodchip. The excess heat from the process is converted into electricity, which is then both used in that plant and sent to the local grid. The syrup from the pot ale reduction is mixed with draff, a co-product from the mashing, and turned into energy rich animal food pellets, feeding the local livestock and generating an additional income to the area.

We also contract Woodland Renewables to treat our spent lees using reed beds, the spent lees has to be treated due to the high copper content.

This allows for 100% local treatment on the peninsula.

Packaging

Our bottle is one of

the lightest in the

industry; it is

produced using

over 50% recycled

clear glass.

We're selling our whisky without a gift box, which reduces waste and shipping weight significantly.

A QR code on the back label provides you with all the information you'll want about that specific bottle of whisky.

Electric Vehicles

Our Sales and Marketing team all drive Electric Vehicles. EV charge points are set up at the distillery and at our bottling hall. The energy for the charge points is generated by solar panels.

Community

The Ardnamurchan trust

The Ardnamurchan Trust is a local charity that purchases a cask of Ardnamurchan new make spirit for every child turning ten, living in West Ardnamurchan. Once the child turns 18 years old, the trust sells the cask back to the distillery and the profit is put in to a fund for the teenager to use in personal development such as University costs, professional licences or certifications. The hope is that the young person will return to the peninsula, bringing with them their new skills, adding value to the local area.

Future plans

MBBR (Moving Bed Bio Reactor)

We are currently installing a new waste water treatment plant at the distillery. The plant will deal with the washing water, currently this is taken away by tankers. The new plant will reduce tanker traffic to the peninsula drastically and make a real difference to our responsible distilling philosophy.

Crush Barley Paper

We use the latest label technology for our Maclean's Nose labels, crushed barley waste is added to the paper pulp, reusing a common co-product in beer and whisky making. We are planning to apply the Crush Barley Paper on to all of our core products in the near future.